Home > Products > New Energy Equipment > The cheapest complete wood pellet production line with high yield

The cheapest complete wood pellet production line with high yield

- Qingdao China

- T/T L/C D/P D/A PayPal

You May Like

-

High Yield wood pellet production easy operation

-

Super Utilities wood pellet pelletizer made in China

-

CE certification wood pellet mill maker best seller

-

low price wood pellet machinary widely used

-

the most popular wood pellet equipment with good feedback

-

small type wood granulator mill with latest technology

Product Details

| Condition | New | Place of Origin | Shandong, China | |

| Brand Name | HMBT | Model Number | ZLG560 | |

| Voltage | 380V, Customized | Power(W) | 90kw | |

| Dimension(L*W*H) | 2600*1300*2300mm | Weight | 6.1T | |

| Certification | CE ISO | Warranty | One Year | |

| After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

The cheapest complete wood pellet production line with high yield

complete wood pellet production line is our main product which has adopted the essence of pellet mill in oversea markets. The core part “double layer die” has unique structural assembly and “rollers” are made of high wearable alloymaterials. These two parts have the following characters: particular design, reasonable structure, low energy, high efficiency and long life etc. Through technical experts’ hard work, our company has developed this typical patent product. This new machine has filled the country blank in vertical feeding for ring die pellet mill and reached the international advanced level.

complete wood pellet production line is mainly applicable for materials which is difficult to mold because of low adhesion rate such as:

1.rice husk, sunflower husk, peanut shell and fruit shell;

2. branch, stem, bark and other wood waste; a variety of crop stalks;

3.rubber, cement, ash and other chemical materials.

complete wood pellet production line can be used in feed mill, wood processing plants, fuel plants, fertilizer plants and chemical plants etc. Since it requires less investment but yield quickly with no risk, which means ZLG series efficient centrifugal pellet mill is an ideal dense compression molding equipment.

The advantage of complete wood pellet production line

A. Five characteristics of complete wood pellet production line

1. Vertical feeding.

2. Die is static while roller is rotary; materials are evenly distributed because of the centrifugal force produced by rotary rollers.

3. Double-layer-die. Double layers can be used independently to cut down costs; and two layers of the die also can be used at the same time to improve efficiency and capacity with fewer energy.

4. Ring die and vertical structure are useful in cooling pelletizing room.

5.Independent and frequency conversion discharge device can improve rate of pelleting.

B. Three differences of complete wood pellet production line

1.Upward mould, special structure, vertically feeding which are help to heat: material drop into the pelletizing room vertically with no other auxiliary power device.

Horizontal type ring die pellet mill: the feed inlet and pelletizing room are set in one side, which make light material feeding into the pelletizing room difficultly. So additional force pressing device is needed for feeding; the lifetime of gearing(gear, bearing) is shorten because the pelletizing room couldn’t dissipate heat.

Flat die pellet mill mainly has two structures, though they can be feed vertically but both of these two structures have many disadvantages which are difficult to get rid of:

(1) Die rotates to make pinch rollers running: material is easily arched which lead to uneven feeding.

(2) Rollers rotate while die is static. This could avoid the arching material, but centrifugal force is caused which will swing the material in the pelletizing room to the periphery; and material distributes unevenly which make the center of the flat die with upward pelletizing holes has no material to press.

2. Efficient centrifugal pellet mill: die is static, roller rotates, materials are centrifugal and distributed around evenly one the inner surface of die because of the high rebounding-effect die.

Ring-die pellet mill’s rollers are static and die is rotary so there is no centrifugal force, materials are distributed unevenly.

Flat-die pellet mill’s rollers can rotate to generate centrifugal force, but the directions between die holes and material force are contradictory.

3. Efficient centrifugal complete wood pellet production line :

(1)double-layer die

(2) multi-function

(3)high efficiency: die has upper and lower parts; customers can choose two different aperture within one die to produce different specifications of pellets. When pelletizing easy bonding materials, we can heighten the rollers and use two-layer dies to get four-fold capacity. No flat die or ring die pellet mill can do this.

Technical data of complete wood pellet production line

Model | Capacity (kg.h) | Power (kw) | Diameter of Pellet(mm) | Weight (T) | Dimension (mm) |

ZLG 560 | 1000-1500 | 90 | 4-12 | 6.1 | 2600*1300*2310 |

ZLG 720 | 1500-2500 | 160 | 4-12 | 7.3 | 2910*1300*2410 |

ZLG 860 | 2000-3000 | 220 | 4-12 | 15 | 3380*1480*3180 |

ZLG 920 | 3000-4500 | 315 | 4-12 | 18.5 | 3900*1780*3500 |

ZLG 1050 | 4500-6000 | 315 | 4-12 | 22 | 4200*1850*3600 |

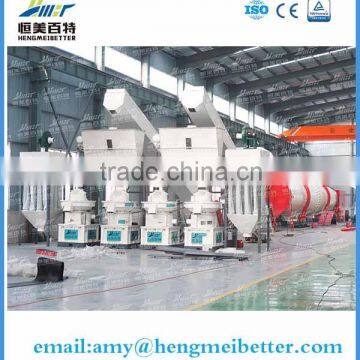

Pictures of complete wood pellet line

Spare parts of complete wood pellet production line

Our complete wood pellet production line

complete wood pellet production line has automatic lubricating system that the grease is injected and filtrated automatically, which can ensure the long time working without stop. It also has dust and cooling system that can reduce the dust during it working and improve the working environment.

complete wood pellet production line have been exported to lots of Europe, South America, Southeast Asia countries, and set agents in Brasil ,Canada, Germany, America, South Africa, Australia, India,Vetnam, Malaysia and so on countries.

In order to quote the best price, please let us know the info:

1, What is your raw material?

2,What is the raw material size?

3,What is the raw material moisture content?

4,What is the capacity do you need?

5, Do you need automatic system or manual packing?

If you are interested in this machine, please do not hesitate to contact us.

We are sure that we will offer you the best pellet mill and service.

We are anticipated to cooperate with you.

Contact Us

- Shandong Hengmei Better Ennovation Equipment Co., Ltd.

- Contact nameHengmei Better Chat Now

- Phone0086-531-83482688

- AddressTaohuashan Industrial Park, Xiuhui Town, Zhangqiu

Product Categories

| Crushing Equipment | Drying/Cooling Equipment | Feedstuff Equipment | Fertilizer Equipment |

| New Energy Equipment | New Products |

New Products

-

high profit wood fuel pelletizer with long service time

-

ce approved hops wood dust sawdust mill with CE & ISO

-

energy saving wood dust pellet mill for pasture

-

homemade wood chips granulator for forestry

-

biomass fuel biomass fuel wood briquette press for farm

-

capacity 0.8-1.5t/h wheat straw pulverizer with wholesale price

-

100-300kg/h wheat straw granulator with low price

-

factory price weeds pellet machine from China

-

CE certificate wood pellet mill from hengmei Better

-

Hengmei Better sawdust pellet machine with high quality

-

CE certificate wood pellet machine and feed pellet machine

-

zlg560 high efficiency sawdust pellet machine made in china

-

zlg560 high efficiency wood pellet machine made in china

-

Widely use branches pellet machine in china environment saving

-

China biomass-energy pellet press manufacturer

-

Hot selling biomass wood pellet mill with supplier

-

Widely use biomass wood pellet mill machine environment saving

-

High efficiency biomass wood pellet making machine for wood working

Popular Searches

- coconut shell

- Pellet Making Machine

- straw machine

- Product Coconut Fiber

- charcoal coffee

- power saver

- Wood Processing Machine

- briquette plant

- Wood Pellet Mill

- Palm Fiber

- Pellet Mill

- Pellet Machine

- briquette making plant

- alfalfa

- Straw Pellet Making Machine

- Wood Pellet Making Machine

- artificial grass machine

- pellet press

- power factor saver

- sawdust briquette

- briquette extruder

- Briquette Production Line

- charcoal powder shaping machine

- charcoal rod extruder

- cocoa shell

- sawdust drying system

- energy saving machine

- Wood Hammer Mill

- Sawdust Hammer Mill

- Wood Chip Hammer Mill

Recommended Products

- Biomass to Biochar Pyrolysis Machine - Automatic Charcoal Making Machine for Wood/Coconut Shell/Agriculture Waste

- Biochar Pyrolysis Machine | Carbonization Furnace for Wood/Coconut Shell/Rice Husk

- Biochar pyrolysis plant | High yield carbonization furnace for charcoal

- Kawise Biomass Pellet Machine – High-Efficiency Pelletizing Solution

- Charcoal Production Machinery for Coconut Shell/Wood/Biomass Briquette Production

- Flat Die Biomass Pellet Mill – Turn Waste into Clean Energy

- Charcoal Briquette Press Machine Converts Sawdust/Coconut Shell/Rice Husk/Wood Into Charcoal

- Maximize Efficiency with the Kawise Small Pellet Machine

- The Growing Demand for Biomass Pellets and the Role of Biomass Pellet Machines

- Maximize Efficiency with a PTO-Driven Pellet Mill for Feed & Biomass Production

- Enhance Your Production Efficiency with Our Diesel Pellet Mill

- Choosing the Right Raw Materials for Biomass Pellet Production

Find Similar Products By Category

- Manufacturing & Processing Machinery > Woodworking Machinery > Wood Pellet Mill

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Hengmei Better

Hi there! Welcome to my shop. Let me know if you have any questions.

Hengmei Better

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile